A Guide to Closures and Zippers for Flexible Packaging

Flexible packaging does many things, but the two things it does best is make product packaging more convenient and functional for a wide range of industries from pet food packaging to coffee packaging.

Flexible packaging does many things, but the two things it does best is make product packaging more convenient and functional for a wide range of industries from pet food packaging to coffee packaging.

One way flexible packaging is able to provide such versatile solutions is by utilizing custom styles and features that help brands tailor their packaging to fit their unique marketplace. From sealing variants to special gusset options and fitments, flexible packaging is adaptable and perfect for multipurpose products and industries.

Another area flexible packaging excels in is closure systems. The technology behind how a package opens and closes is crucial to maintaining product integrity while also giving customers a package that’s convenient and easy-to-use. We’ve highlighted some of the most common (and most useful) zippers and closure systems for flexible packaging below.

Press-to-Close Zippers

Press-to-close zippers are one of the most effective resealable storage options on the market and work well with nearly every flexible packaging type including stand-up pouches, box pouches and shaped pouches.

This closure style has become an old favorite due to its simplicity and multipurpose capabilities. Whether you need a resealable pouch for cupboard storage, fridge storage or freezer storage, press-to-close zippers are a great, cost-effective solution.

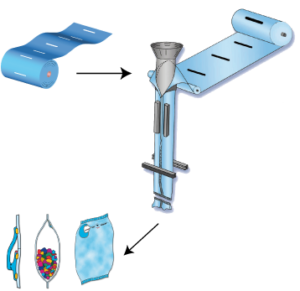

Inno-Lok®

When applying zipper line falls outside of your packaging budget, roll stock with pre-applied zipper technology is a low-cost alternative. These pre-applied zippers mesh well with both preformed pouch and roll fed film products.

Inno-Lok® simplifies production line complexities and is currently a popular closure style in the frozen food, snack food and candy industries.

Pour & Lok®

Cut from the same cloth as the Inno-Lok® technology described above, Pour & Lok® zippers are specifically designed to enhance and transform side gusset pouches into a re-closable pour spout. Which makes it an ideal closure system for pet food and snack food packaging.

One thing that makes Pour & Lok® unique is that it works in conjunction with the press-to-close zipper closure style to create a large, foldable opening within the pouch’s gusset adds more functionality for scoop-able products.

Spouts and Fitments

While zipper closure systems work great for select products and industries, spouts and fitments make it possible for brands to provide flexible packaging solutions for beverages, household cleaning products and even certain cosmetic and personal care products.

Combined with new innovations in high-barrier film technology, spouts and fitments allow flexible packaging to cross over into previously untapped spaces including motor oil product packaging, baby food packaging and more.

Which should you choose?

The type of closure system you choose for your flexible packaging project relies on several different factors. What’s the application? What materials and ingredients are involved? How should the product be stored?

When you partner with Eagle Flexible Packaging, you’ll work alongside our expert team of packaging strategists who will help you answer those questions and more so you can make the smartest decision for your product.

Fill out our sidebar form today to get started and learn more about our unique zipper and closure solutions.